Home > Photo Etching Metal > Beryllium Copper Photo Etching

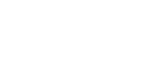

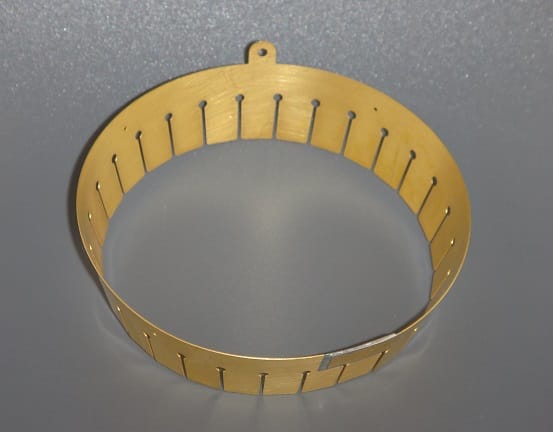

Beryllium Copper Photo Chemical Machining

Complete Beryllium Copper Photo Etching Services

Beryllium copper is an alloy of copper and 0.5% to 3% beryllium. It is non-magnetic and non-sparking, highly ductile, abrasion resistant, and resistant to non-oxidizing acids.

Beryllium copper, often referred to simply as beryllium, can be heat-treated to improve its already high strength, and holds its shape well when formed, making it ideal for various electronics applications.

Vaga Industries has extensive experience in photo etching beryllium copper, and can deliver the high precision, tight tolerance parts your application requires. Request a quote today or contact us for more information.

Vaga Industries’ Beryllium Copper Photo Chemical Machining Services

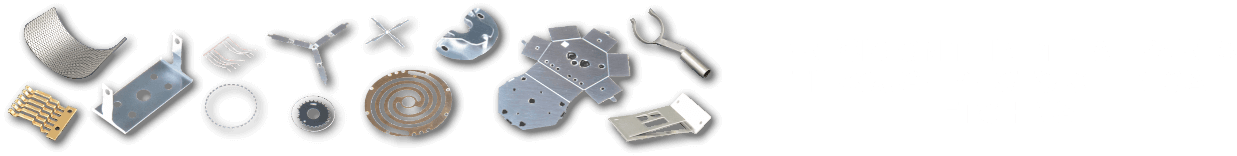

Vaga Industries uses photo chemical machining to produce high precision, tight tolerance beryllium copper parts. Our photo etched beryllium copper parts are custom manufactured to meet our customers’ exact design requirements. Beryllium copper is available in various grades, and we can help you choose the right one for your application.

Cost effective and highly repeatable, photo etching beryllium copper is an ideal method for producing simple or complex parts in high or low volumes. It is also well-suited for part prototyping.

Chemical etching produces beryllium parts that are burr-free, with no heat affected zones, no work hardening, and unaffected surface finishes. Half or partial etching techniques can be used to create intricate details, such as lettering or logos, that vary in thickness but do not penetrate the material completely.

We offer full-service forming and heat-treating for beryllium copper parts. We have a large inventory of beryllium copper available, and can provide all the materials your project requires. We can also work with customer supplied beryllium copper.

Request a quote today, or contact Vaga Industries for more information on our capabilities for photo chemical machining beryllium copper.