Photochemical etching materials

Vaga Industries specializes in creating precision-etched components from a diverse range of metals and alloys.

When performed properly, photochemical etching is a fast, efficient way to produce practically two-dimensional parts from a wide range of metals.

Because of their varying compositions, different metals require different etching solutions and processing times. Our team will work with you to determine the ideal construction for your parts and components.

Trusted expertise for over 50 years

From our world-class production facility equipped with the latest state-of-the-art technology, we offer photo chemical etching services of the highest quality for the materials below, or any other materials you require.

Metals and alloys

Aluminum etching

We offer AS 9100-accredited aluminum etching service of unrivaled accuracy and precision. Highly repeatable and consistent, our aluminum etching process can create intricate, complex geometries for designs of exceptional durability and reliability. As a cost-effective, versatile, zero-distortion alternative to stamping and laser cutting, our aluminum etching is the preferred choice of the following high-tech industries.

- Aerospace: Heat exchangers, engine parts, aircraft structures

- Automotive: Heat shields, interior components, intake grillers

- Medical: Surgical instruments, medical implants, diagnostic tools

- Electronics: PCBs, heat sinks, electronic enclosures

- Computers: Heat sinks, electromagnetic shielding, fan brackets

Brass etching

We can create brass components to meet your specific requirements for any decorative and functional applications. Our brass etching service uses market-leading techniques to maintain intricate details, superior surface finish, and tight tolerances. Vaga Industries is a trusted supplier of precision etched brass components for industries like jewelry, architecture, musical instruments, and those listed below.

- Automotive: Fuel system components, trim pieces, interior accents

- Electronics: Electrical contacts, connectors, and terminals

Copper etching

Vaga Industries offers a comprehensive copper etching service, providing precise, rapidly conductive, and miniaturized components from a variety of copper-based alloys, including beryllium copper. Our chemical copper etching process is non-thermal and non-contact, ensuring burr-free, stress-free, flat copper components of flawless integrity compared to conventional methods of stamping, waterjet cutting, or laser cutting.

- Aerospace: Heat sinks, heat spreaders

- Medical: Surgical instruments, medical implants, diagnostic devices

- Electronics: PCBs, electrical contacts, connectors

- Computers: PCBs, RF/microwave components, heat sinks

Inconel etching

We offer a market-leading inconel etching service, supplying burr-free, stress-free components of high intricacy, surface quality, and complexity with tight tolerances. Our inconel etching process is non-thermal and non-contact, ensuring the integrity for applications that require precise geometries to meet performance and safety standards. We are a preferred supplier for the following industries.

- Aerospace: Turbine blades, heat exchangers, RF/Microwave components

- Automotive: Fuel injector nozzles, sensors, brake components

- Medical: Surgical instruments, stents, pacemaker components

- Electronics: Lead frames, PCBs, EMI/RFI shielding

- Computers: Battery contacts, Flexible printed circuits (FPCs), speaker grilles

Steel and stainless steel etching

Vaga Industries offers a steel and stainless steel etching service of unparalleled precision. Perfected over 50 years, our steel etching process allows us to create intricate designs and components free of burrs or mechanical stress. With endless applications and customization possibilities, our etched steel parts retain their integrity, corrosion resistance, and durability for many applications, even in the harshest environments.

- Aerospace: Brackets, clips, shrouds

- Automotive: Fuel injectors, clutch plates, brake calipers

- Medical: Surgical instruments, implantable devices, device housings

- Electronics: EMI/RFI shielding, connectors, heat sinks

- Computers: Heat spreaders, hard drives, connectors

Titanium etching

We offer titanium etching services of the highest accuracy, integrity, and surface finish for all grades of titanium. Our proven process for titanium etching guarantees precise designs, features, and geometries with the highest tolerances, always 100% free of burrs, work hardening, and heat distortion. Our expert engineers are happy to help you select the right grade for your unique application.

- Aerospace: Turbine blades, antenna mounts

- Automotive: Valve springs, racing chassis brackets

- Medical: Orthopedic implants, dental prosthetics and abutments

- Electronics: Heat sinks, enclosures

- Computers: CPU heat spreaders

Chemical photo etching capabilities

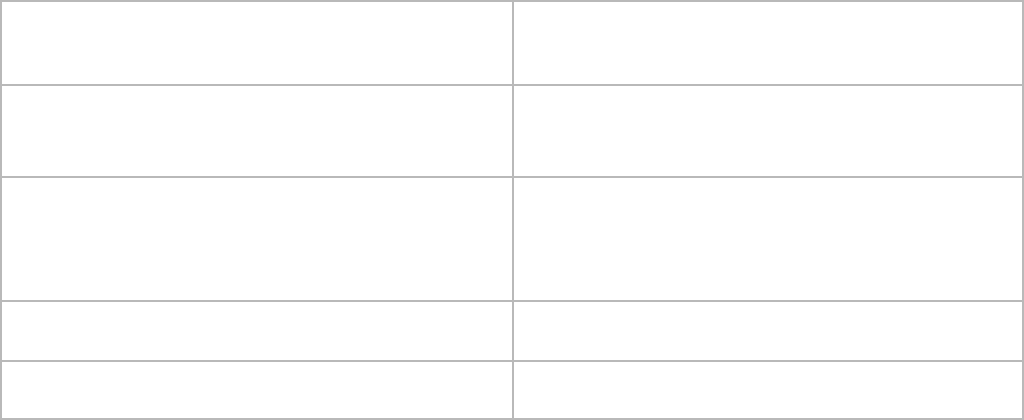

Specifications

Minimum thickness: 0.001”

Maximum thickness: 0.040”

Maximum panel size: 54”x28”

Minimum feature size: 110% of thickness, up to 0.006”

Minimum land area/Web size: 60% of material thickness, up to 0.002”

Minimum etched tolerance: ±10% of material thickness, up to ±0.001”

Minimum inside corner radii: = to material thickness

Minimum outside corner radii: 75% of material thickness, and sharper as needed

Our value added services

Vaga Industries offers a variety of post-production services to ensure the performance, appearance, and durability of your metal components, as well as streamline your fulfillment process.

- Plating

- Forming

- Heat treating

- Passivation

- Electropolishing

- Lapping

- Coating (Teflon, etc.)

- Marking/ink stamping

- Kitting/bagging

- Assembly

Let our experience be your guide.

No matter how complex your designs, no matter if you need 10 pieces or 100,000, chemical etching can produce perfectly repeatable parts. How?

Shapes are blocked out using a custom photoresist tooling. The metal is then submerged in an acidic bath, which dissolves any unprotected material. Our chemists use a variety of standard and specialized chemical combinations to provide highly effective and reliable photo etching.